AAC Autoclaves

What is AAC ?

Aerated Autoclaved concrete block (light block) is a light and porous building material. Aerated concrete is a compound of cement, lime, fly ash, and gas former (aluminum powder). It is a high-efficient heat-insulating material made through the molding and steam curing processes. While AAC was originally used in colder climates where the material provided the thermal resistance to keep the interior warm; it is being used more and more worldwide where the external temperature is high and air conditioning is needed. As a result of using AAC, the energy use (and therefore the carbon emissions) is significantly lower than for other forms of construction.It has a wide prospect of market. It is the main building material in the future. It can be made into many kinds of bricks (for example: 600×200×100mm, 80×80×180mm, 240×115×53mm, 600×200×125mm), they could be used in industry building as well as common building. They are becoming more and more popular in the world. In the future, they will replace the Clay brick completely.

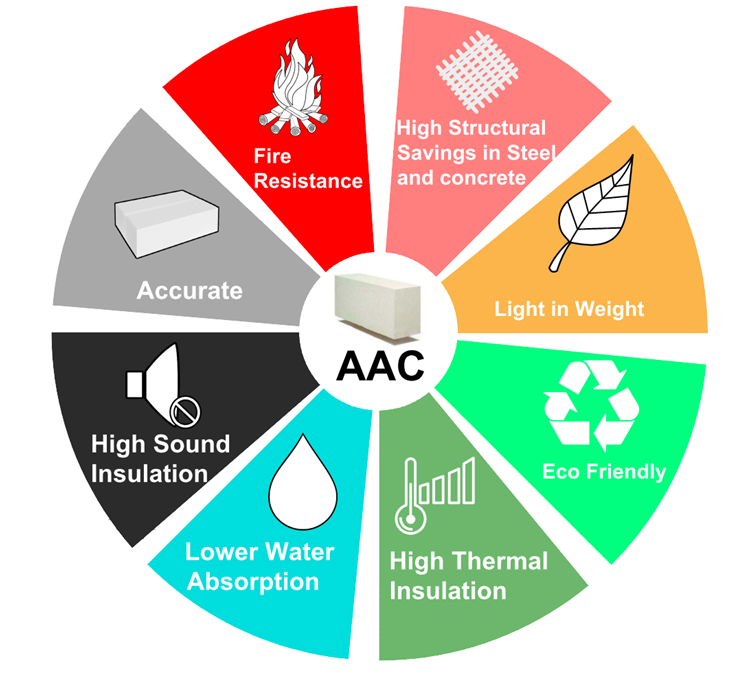

properties of AAC

The apparent density of the aerated concrete is small. Common concrete density is usually 1600-2400kg/m3, but density of aerated concrete is 500kg/m3, 600kg/m3,700kg/m3 and the thermal conductivity of it is even several times smaller than that of the clay brick. Therefore, the aerated concrete wall of 24cm wide is better than the brick wall of 37 cm wide.

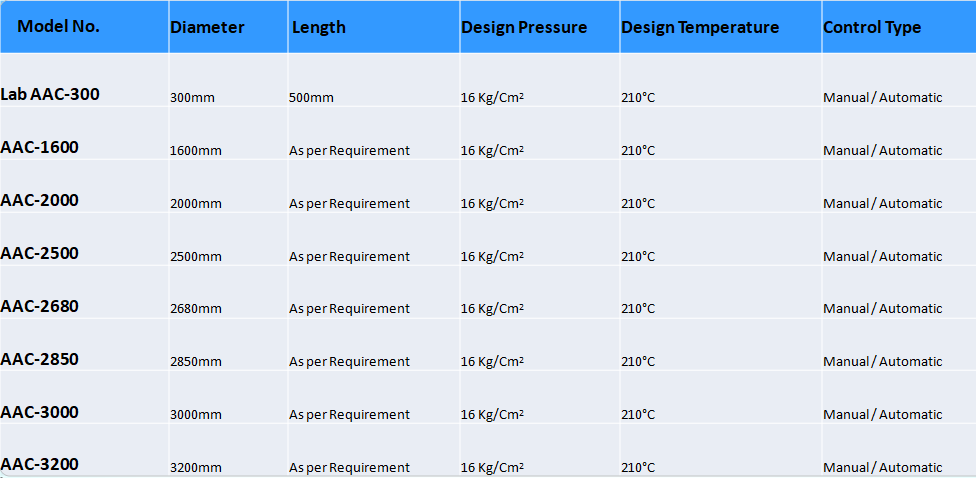

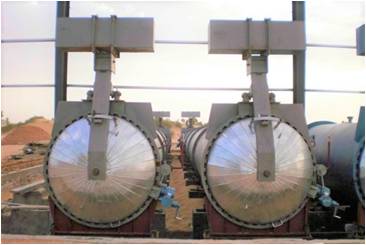

HPEW AAC Autoclave

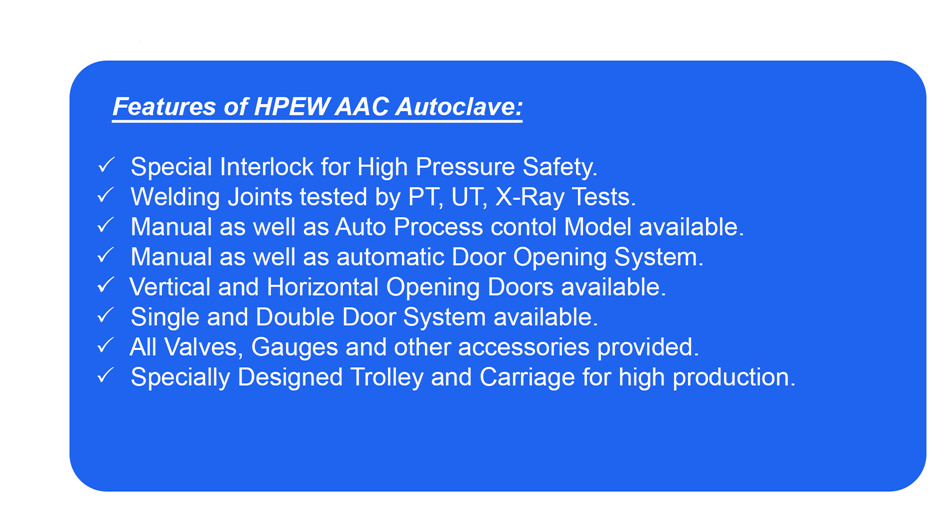

H. P. Engineering Works, Vapi is a Pioneer in Manufacturing high pressure Vulcanizer working pressure from 5 kg/Cm2 to 20 kg/Cm2 for fast production of all types of autoclaved aerated bricks and aerated concrete Etc.AAC Autoclave is a kind of large steam curing pressure vessel and the key equipment to produce autoclaved aerated bricks and aerated concrete. This kind of industrial autoclave is composed of autoclave body, cover, reducer, safe operation device, support saddle and control system. The design and quality of autoclave for AAC plant can affect the strength, sturdiness and comprehensive quality in the AAC process. The autoclaved aerated bricks are steamed or cured under high temperature and high pressure using saturated water vapor as the working media. Our autoclave for AAC blocks is designed as per ASME Code which high levels of safety, high performance, flexibility process control and easy to operate. HPEW Autoclave is key equipment which has a widely application in building material factory to autoclaved cure different kinds of building materials. Convenient operation, security and reliable are its advantages.

Curing Process of AAC in autoclave

Autoclaved high-pressure steam curing is used to improve compressive strength of aerated concrete. When the reinforced aerated concrete slab is manufactured, the mortar is mixed well and poured into the steel mold, and the strength of the aerated concrete will be reached only after cured under high temperature and pressure (usually 200°C, 15 atm., and about 24 hours) in the autoclave. When the slab is cooled down, the prestress is established certainly on its section due to the difference in thermal deformations between the reinforcement and aerated concrete, as the linear expansion coefficients of both materials are unequal. This is called self-prestressing and is favorable for the cracking resistance of the slab, and an initial camber is obviously formed. The AAC products are ready for use within 24 h (the strength is generally equivalent to 28 days under ambient curing). Thus resulting in Very High Production as compared to standard clay bricks.

Quality Control And Safety

At H. P. Engineering Works, we understand the importance of quality and safety in autoclave operations. All of our autoclaves are equipped with state-of-the-art safety features. HPEW Autoclaves / Vulcanizers comes equipped with Safety Features. The high-pressure, high-temperature environment produced inside an autoclave can be dangerous, so safety a high priority in our HPEW autoclave designs. We ensure our design incorporates workplace safety and prevent operator accidents.Additionally, before shipment, each unit is rigorously tested for quality. After delivery we send our engineers On Site for Commissioning of Autoclaves / Vulcanizers and provide training to Clients related to Autoclave Features and Functions. Our Engineers are also available for on-line technical support. At HPEW, we aim to provide our customers with the highest quality products and services for their autoclaving needs. Our in-house engineering team offers complete custom engineering and manufacturing capabilities to design, develop, and deliver an autoclave unit tailored to meet unique specifications. Contact our team to learn more about our vulcanizing autoclaves. For pricing details or assistance choosing an autoclave unit for your needs, request a quote.