Composite Autoclaves

What are composites?

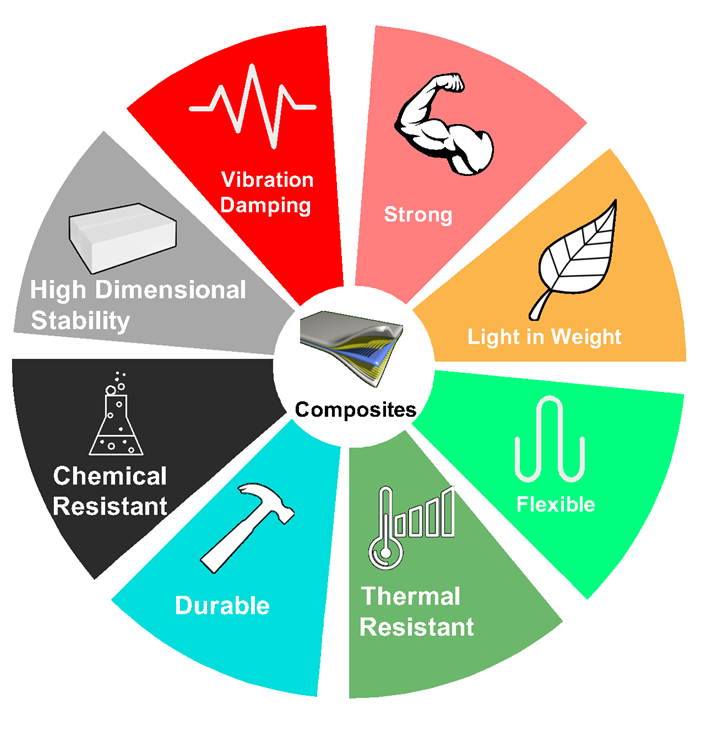

A composite material (also called a composition material or shortened to composite, which is the common name) is a material made from two or more constituent materials with significantly different physical or chemical properties that, when combined, produce a material with characteristics different from the individual components. The individual components remain separate and distinct within the finished structure, differentiating composites from mixtures and solid solutions.Composites are used in a wide variety of markets, including aerospace, architecture, automotive, energy, infrastructure, marine, military, sports and recreation. Composites have permeated our everyday lives: They are used in the cars we drive, golf clubs we swing, pipes that remove wastewater from our neighborhoods and much more. Some applications, such as rocket ships, probably wouldn’t get off the ground without composite materials. Composites offer many benefits. Key among them are strength, light weight, corrosion resistance, design flexibility and durability.

HPEW Composite Autoclaves

On going changes in aerospace composites, composite racing systems and ballistics require next-generation advanced composite curing autoclaves. HPEW composite autoclaves—utilized for composite polymer curing—are specifically engineered for these industries. These requirements often require extreme attention to detail when engineering composite autoclaves, as opposed to other industrial autoclaves such as waste sterilizers. In addition, growing demands for efficiency and cost improvements in aircraft manufacturing mean that autoclave designs must meet diverse and complex design requirements suited to both thermoset and thermoplastic composite materials. The manufacture of composite autoclaves requires advanced components, attention to detail, and strict adherence to quality control standards. Our dedicated team of design, production, and quality control personnel dedicate themselves to the highest level of performance in producing composite autoclaves that perform according to the specifications of our clients.FEATURES OF AUTOCLAVES OFFERED BY HPEW

Our line of vulcanizing autoclaves incorporates several design features aimed toward facilitating operations for customers. Key features include:

QUICK OPENING DOOR

All HPEW make Autoclaves come with Quick Opening /Locking Door Mechanism. HPEW make autoclaves have a option of hydraulic powered doors that allow for quick and safe opening and locking of the unit. Door Open / close, Lock/Unlock within one minute. The door systems feature a long-lasting ring gasket and special air system for perfect Door Sealing and Zero Leakage.

BASIC TEMPERATURE AND PRESSURE CONTROLS

HPEW make autoclave / vulcanizer comes with a temperature and pressure control unit.

PROGRAMMABLE LOGIC CONTROLLER

HPEW make Autoclaves / Vulcanizers come with Programmable logic controllers which provide autoclave operators with greater flexibility in the programming of autoclave process cycles. This quality allows them to optimize cycles to achieve the desired process and product results. The Controller included in HPEW Autoclaves have modem hookup capabilities.

SPECIAL TROLLEY AND CARRIAGE

At HPEW we also offer Special Trolley and Carriage for Autoclaves / Vulcanizers. Trolleys and Carriage are specifically designed for your product and according to your factory setup layout. These Special Trolleys and Carriages boost your Production output per batch and also reduce idle time of Autoclave in between curing cycles which ultimately leads to more profit.

QUALITY CONTROL AND SAFETY

At H. P. Engineering Works, we understand the importance of quality and safety in autoclave operations. All of our autoclaves are equipped with state-of-the-art safety features. HPEW Autoclaves / Vulcanizers comes equipped with 10 Safety Features. The high-pressure, high-temperature environment produced inside an autoclave can be dangerous, so safety a high priority in our HPEW autoclave designs. We ensure our design incorporates workplace safety and prevent operator accidents.Additionally, before shipment, each unit is rigorously tested for quality. After delivery we send our engineers On Site for Commissioning of Autoclaves / Vulcanizers and provide training to Clients related to Autoclave Features and Functions. Our Engineers are also available for on-line technical support. At HPEW, we aim to provide our customers with the highest quality products and services for their autoclaving needs. Our in-house engineering team offers complete custom engineering and manufacturing capabilities to design, develop, and deliver an autoclave unit tailored to meet unique specifications. Contact our team to learn more about our vulcanizing autoclaves. For pricing details or assistance choosing an autoclave unit for your needs, request a quote.