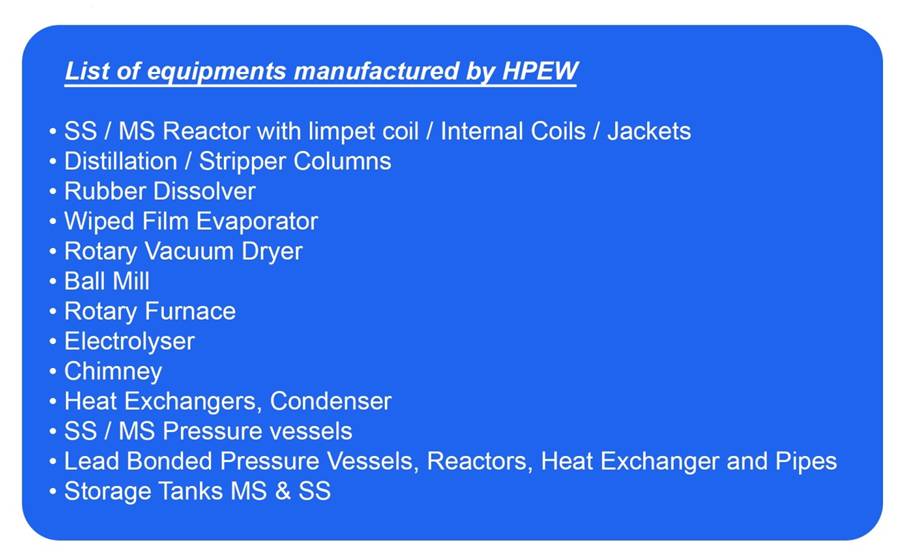

Process Equipments

HPEW is a leading manufacturer in Gujarat (Vapi) state of India, of various types of Chemical Pressure Vessels, Columns, Heat Exchanger, Reactors, Fabricated Pipes, Chimney Pipe Coil, Storage Tanks. Equipments are manufactured from various materials like Stainless Steel, Alloy Steel, Carbon Steel, Cladded Steel, and they are widely used in process industries like Petrochemical, Chemical, Fertilizers, Food Processing, Refineries, Oil & Gas. Equipments are manufactured as per various codes of construction under third party inspection as well as client inspection.

Lead Bonded Equipments

HPEW has great experience in the field of Lead Bonding, HPEW specializes in manufacturing of Agitators, Reactors, Columns, Storage tanks, Pipes with Lead lining. HPEW Manufactures Lead Bonded Equipments under third party inspection agencies also.

Storage and Process Vessels

H. P. Engineering Works manufactures a wide variety of storage and process vessels for the Food Processing and Manufacturing Industries, Beverages Industries, Dairy, Fertilizers, Chemicals and Pharmaceutical Industries including the following equipments:Large storage vessels.

Vessels for custom mixing and blending.

ASME Pressure vessels with Section VIII Division-1.

Horizontal blenders and mixers.

Heat transfer jacketed tanks with ASME Section VIII Division-1.

Industrial Process Reactors Systems and Agitators

H. P. Engineering Works is involved in manufacturing and supplying a broad range of Industrial Process Reactors & Agitators. We offer Stainless Steel Reactors, Jacketed Reactors, Chemical Reactors, used widely in various chemical industries. Industrial Agitators are fabricated in various types like turbines, anchor, propeller, pitched blade turbines based on mixing requirements. The agitators are fabricated in MS and can be lined with other materials. These Reactors and Agitators are available in different specifications as per the requirements of our clients.

Storage tank, Vessels, Silos

H. P. Engineering Works is a pre-eminent organization engaged in manufacturing & supplying of both MS and SS Storage Tanks that are widely used across the world. These tanks are manufactured as per the international norms and standards using the latest technology and high-grade equipments. HPEW is also engaged in manufacturing and supplying Liquid Storage Silos and Mixing Tanks, assuring use of premium quality raw materials and ensuring high-quality products to our end users.

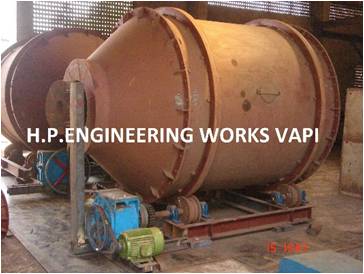

Well Equipped Manufacturing Facility

HPEW has state of the art manufacturing facility to fabricate various types of process equipments.HPEW can handle single job,

Max Weight: 50 Tonnes,

Max Dia: 4.5 Mtr

Max Length: 35 Mtr

Maximum Thickness: 50 mm.

Manufacturing Facility:

Overhead EOT Crane

Hydraulic Press

Plate Bending Machine

Section bending Machine

Lathe Machine

HMT Radial Drilling Machine

Plasma Cutting Machine

Arc Welding Machines

Tig Welding Machines

Mig Welding Machines Etc.

Testing Facilities:

Hydrostatic Test up to - 100 Kg/Cm2

Pneumatics Test up to - 10 Kg/Cm2

Dye Penetrate Check

Ultrasonic Testing

Radiographic Testing

Chemical and Physical analysis

Painting, Acid Cleaning, Pickling and Neutralizing

Post and Pre-weld heat treatment (stress relieving, normalizing, annealing etc.)

In House Bending, Machining & Drilling Facility

HPEW has in house Shell & Dish bending facility, machining facility & Drilling Facility. Due to all in house shell & dish bending, Machining & Drilling we need not rely on other companies to complete our work which ultimately leads to faster and timely delivery of Equipments and completion of Projects.Our welders are selected and tested to meet standards as per ASME IX and has remained dedicated to maintaining a high standard of professional performance and integrity in Engineering design & fabrication. Our pressure vessels are tested for (NDE) 100% Radiography, DP test, MPI, UT and Hydro / Pneumatic test. We also provide Post weld heat treatment for Pressure vessels on specific vessels that demand application in high temperature atmospheres.

Our company believes strongly that the best solutions emanate from a combination of Engineering innovation, Comprehensive project management, Modern Technology, Cost effective Machinery, Automation and Monitoring systems.