Autoclave and Vulcanizer

Autoclaves are large chambers that employ high pressures and temperatures to facilitate industrial processes. They are generally used to expose equipment and supplies to high-temperature saturated steam for decontamination or sterilization applications. However, they also have many other uses, such as in vulcanization operations.Vulcanization is a chemical process applied to rubber or other natural compounds with elastomeric properties. Industry professionals use it to increase the elasticity and decrease the plasticity of the material, resulting in improvements to many of its physical and performance characteristics, such as resilience, tensile strength, viscosity, hardness, and weather resistance. Vulcanizing autoclaves—also known as vulcanizers—facilitate this process, enabling rubber manufacturers to quickly and easily convert natural rubber and plastic into cured parts and products.

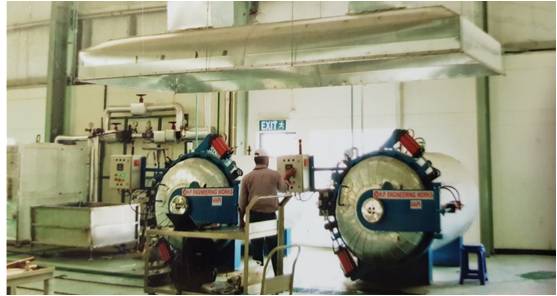

H. P. ENGINEERING WORKS, VAPI is a Pioneer in Manufacturing high pressure Vulcanizer working pressure from 5 kg/cm2 to 12 kg/cm2 for fast production of all types of Hose pipes, Extruded items, Rubber roller, Rubber lining in tanks, Rubber Cables, Rubber lined valves, Fenders etc.

At H. P. Engineering Works, we manufacture a full line of vulcanizing autoclaves—including direct steam heat, indirect steam heat, indirect electric heat, and models—suitable for use in a wide range of industrial applications. Designed and engineered for superior functionality, our autoclaves help our customers meet some of the strictest industry standards and specifications

Types of Vulcanizers offered by H. P. Engineering Works

Vulcanizing autoclaves are available in several variations to suit different vulcanization needs. For example, autoclaves with indirect heat transfer systems employ a heat exchanger to distribute heat generated by an external heat source to the working envelope of the autoclave, while autoclaves with direct heat transfer systems have heating elements that are located within the autoclave itself. Additionally, the heat can be generated through electric, steam, gas, or thermal oil means. At HPEW, we offer the following types:FEATURES OF VULCANIZING AUTOCLAVES OFFERED BY HPEW

Our line of vulcanizing autoclaves incorporates several design features aimed toward facilitating operations for customers. Key features include:

QUICK OPENING DOOR

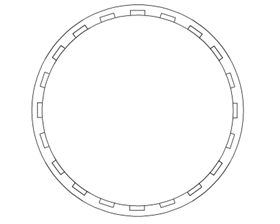

Nut - Bolt type of Vulcanizers are outdated since last 30 years since it does not offer perfect seal and takes 20 to 30 minutes to Close and Lock resulting in decreased production. All HPEW make Vulcanizers come with Quick Opening /Locking Door Mechanism. HPEW make autoclaves have a option of Pneumatic and hydraulic powered doors that allow for quick and safe opening and locking of the unit. Door Open / close, Lock/Unlock within one minute. The door systems feature a long-lasting ring gasket and special air system for perfect Door Sealing and Zero Leakage.

BASIC TEMPERATURE AND PRESSURE CONTROLS

PROGRAMMABLE LOGIC CONTROLLER

HPEW make Autoclaves / Vulcanizers come with Programmable logic controllers which provide autoclave operators with greater flexibility in the programming of autoclave process cycles. This quality allows them to optimize cycles to achieve the desired process and product results. The Controller included in HPEW Autoclaves have modem hookup capabilities.

Special Trolley and Carriage

At HPEW we also offer Special Trolley and Carriage for Autoclaves / Vulcanizers. Trolleys and Carriage are specifically designed for your product and according to your factory setup layout. These Special Trolleys and Carriages boost your Production output per batch and also reduce idle time of Autoclave in between curing cycles which ultimately leads to more profit.CONSULTANCY

QUALITY CONTROL AND SAFETY

At H. P. Engineering Works, we understand the importance of quality and safety in autoclave operations. All of our autoclaves are equipped with state-of-the-art safety features. HPEW Autoclaves / Vulcanizers comes equipped with 10 Safety Features. The high-pressure, high-temperature environment produced inside an autoclave can be dangerous, so safety a high priority in our HPEW autoclave designs. We ensure our design incorporates workplace safety and prevent operator accidents.

Additionally, before shipment, each unit is rigorously tested for quality. After delivery we send our engineers On Site for Commissioning of Autoclaves / Vulcanizers and provide training to Clients related to Autoclave Features and Functions. Our Engineers are also available for on-line technical support. At HPEW, we aim to provide our customers with the highest quality products and services for their autoclaving needs. Our in-house engineering team offers complete custom engineering and manufacturing capabilities to design, develop, and deliver an autoclave unit tailored to meet unique specifications. Contact our team to learn more about our vulcanizing autoclaves. For pricing details or assistance choosing an autoclave unit for your needs, request a quote.

|

Model No. |

Diameter |

Length |

Pressure |

Control Type |

|

Lab V-300 |

300mm |

500mm |

1Kg/Cm2 upto 15kg/Cm2 |

Manual / Automatic |

|

V-800 |

800mm |

As per Requirement |

1Kg/Cm2 upto 15kg/Cm2 |

Manual / Automatic |

|

V-1000 |

1000mm |

As per Requirement |

1Kg/Cm2 upto 15kg/Cm2 |

Manual / Automatic |

|

V-1200 |

1200mm |

As per Requirement |

1Kg/Cm2 upto 15kg/Cm2 |

Manual / Automatic |

|

V-1500 |

1500mm |

As per Requirement |

1Kg/Cm2 upto 15kg/Cm2 |

Manual / Automatic |

|

V-1800 |

1800mm |

As per Requirement |

1Kg/Cm2 upto 15kg/Cm2 |

Manual / Automatic |

|

V-2000 |

2000mm |

As per Requirement |

1Kg/Cm2 upto 15kg/Cm2 |

Manual / Automatic |

|

V-2500 |

2500mm |

As per Requirement |

1Kg/Cm2 upto 15kg/Cm2 |

Manual / Automatic |

|

V-2800 |

2800mm |

As per Requirement |

1Kg/Cm2 upto 15kg/Cm2 |

Manual / Automatic |

|

V-3200 |

3200mm |

As per Requirement |

1Kg/Cm2 upto 15kg/Cm2 |

Manual / Automatic |